Kaeser Compressor Troubleshooting: A Comprehensive Guide

Accessing crucial Kaeser compressor PDF manuals is vital for effective troubleshooting; locate the correct document online to understand system specifics and error codes.

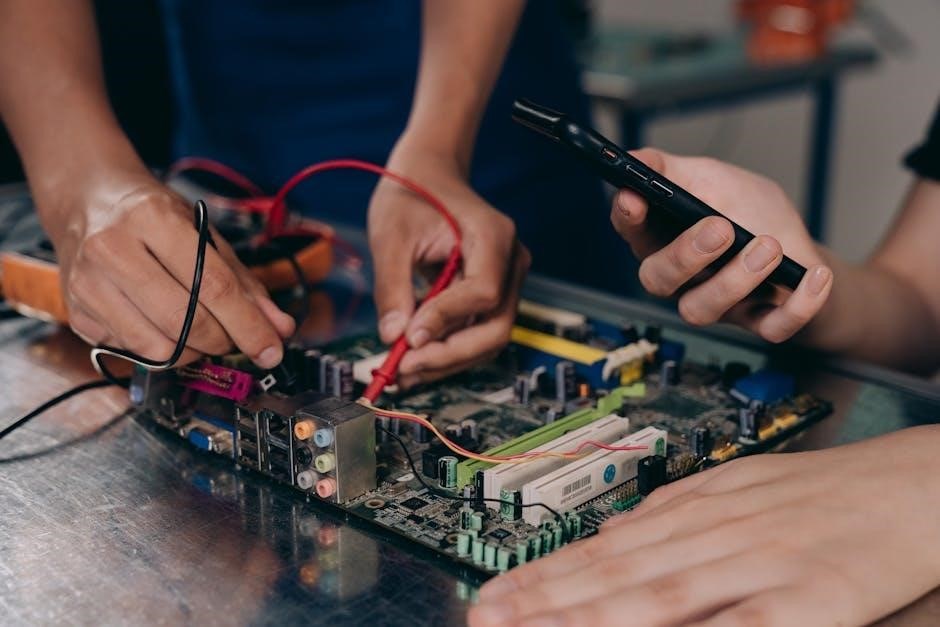

Understanding Kaeser Compressor Systems

Kaeser compressors are renowned for their robust engineering and efficiency‚ but even the most reliable systems require diligent maintenance and troubleshooting. PDF manuals are indispensable resources‚ detailing specific model configurations‚ component locations‚ and operational parameters. These documents outline the intricate interplay between the compressor’s core elements – the airend‚ motor‚ control system‚ and cooling apparatus. Understanding these interactions is paramount when diagnosing issues. Accessing the correct PDF manual‚ specific to your Kaeser model (CSD‚ CXC‚ etc.)‚ provides schematics‚ error code explanations‚ and step-by-step procedures for resolving common problems‚ ensuring optimal performance and longevity.

Common Kaeser Compressor Error Codes

Kaeser compressors utilize a sophisticated error code system to pinpoint malfunctions. The corresponding PDF manual is essential for deciphering these codes‚ as each represents a specific fault within the system. Common errors relate to pressure deviations‚ motor protection triggers‚ or control system failures. Decoding these alerts requires referencing the manual’s dedicated troubleshooting section. Ignoring error codes can lead to escalating damage. The manual provides detailed explanations‚ potential causes‚ and recommended corrective actions for each code‚ enabling technicians to efficiently diagnose and resolve issues‚ minimizing downtime.

Low Air Pressure Issues

Addressing low air pressure in a Kaeser compressor begins with consulting the official PDF manual. It details potential causes‚ ranging from insufficient air delivery to system leaks. The manual guides technicians through checking air filter integrity‚ verifying pressure settings‚ and inspecting for obstructions. Proper diagnosis relies on the manual’s schematics and troubleshooting flowcharts. Low pressure can stem from failing components like the intake valve or a malfunctioning control system. The manual provides specific testing procedures and repair instructions‚ ensuring accurate resolution and optimal performance.

Insufficient Air Delivery

The Kaeser compressor PDF manual is paramount when facing insufficient air delivery. It outlines a systematic approach‚ starting with verifying the inlet air supply and filter condition. The manual details how to check for obstructions in the intake piping and assess the performance of the air end. Specific torque specifications for component tightening are crucial‚ as detailed in the manual. Reduced delivery can also indicate issues with the compressor’s control system or internal components. Referencing the manual’s diagnostic charts aids in pinpointing the root cause and implementing effective repairs.

Leak Detection in the System

The Kaeser compressor PDF manual provides detailed procedures for leak detection. It emphasizes the importance of a thorough visual inspection of all air lines‚ fittings‚ and connections. The manual recommends using a soap solution to identify even minor leaks‚ noting specific areas prone to failure. Pressure testing procedures‚ including required pressure levels and duration‚ are clearly outlined. Understanding the system’s layout‚ as depicted in the manual’s schematics‚ is crucial for efficient leak tracing. The manual also details proper repair techniques for damaged components‚ ensuring a lasting seal.

Oil Carryover Problems

The Kaeser compressor PDF manual dedicates sections to diagnosing and resolving oil carryover issues. It details the function of the oil separation system and potential failure points. Troubleshooting steps include checking oil levels‚ separator efficiency‚ and the condition of internal filters. The manual provides diagrams illustrating the oil circuit and separator assembly. It specifies acceptable oil carryover limits and outlines procedures for testing air quality. Proper maintenance schedules‚ as detailed in the manual‚ are critical for preventing oil contamination. Component replacement instructions are also included.

Identifying the Source of Oil Contamination

The Kaeser compressor PDF manual emphasizes a systematic approach to pinpointing oil contamination origins. It instructs users to first inspect the oil separator for damage or excessive buildup. Next‚ examine the oil cooler for leaks and proper function. The manual details how to check for worn piston rings or valve seals‚ common sources of internal leakage. It also highlights the importance of verifying correct oil levels and types. Diagrams within the manual aid in locating these components. Proper diagnostic procedures‚ as outlined‚ minimize downtime.

Oil Separator Maintenance & Replacement

The Kaeser compressor PDF manual provides detailed procedures for oil separator maintenance and replacement. Regular inspection‚ typically every 500-1000 hours‚ is crucial. The manual illustrates how to disassemble‚ clean‚ and inspect the separator elements for damage or clogging. Replacement intervals depend on operating conditions and oil quality. Specific torque specifications for reassembly are clearly outlined. The manual stresses using only genuine Kaeser replacement parts to maintain performance and warranty validity. Proper disposal of used oil and separator elements is also addressed.

Compressor Overheating

The Kaeser compressor PDF manual details troubleshooting steps for overheating issues. It emphasizes checking the cooling system – radiator fins for blockage‚ fan operation‚ and coolant levels. The manual provides temperature thresholds for alarm and shutdown conditions. It instructs users to verify proper ventilation around the compressor. Lubrication system analysis‚ including oil levels and filter condition‚ is also covered. Electrical connections and motor overload protection are examined. The manual warns against operating the compressor outside its specified temperature range.

Cooling System Checks

The Kaeser compressor PDF manual prioritizes cooling system checks during overheating troubleshooting. It details inspecting the radiator for debris blockage‚ ensuring proper airflow across the fins. Verify the cooling fan’s operational status – check for rotation and unusual noises. The manual instructs on assessing coolant levels and condition‚ noting any discoloration or contamination. Inspect hoses and connections for leaks or damage. It also covers checking the thermostat’s functionality and verifying proper operation of any cooling water systems.

Lubrication System Analysis

The Kaeser compressor PDF manual emphasizes lubrication system analysis when addressing overheating or performance issues. It instructs checking oil levels and condition‚ noting any signs of contamination‚ like metal particles or water. Inspect oil filters for blockage and adhere to recommended replacement intervals. The manual details verifying proper oil pressure using the system’s gauges. Check oil lines and connections for leaks or restrictions. It also covers assessing the oil pump’s functionality and ensuring adequate oil flow to all critical components.

Motor Protection & Faults

The Kaeser compressor PDF manual dedicates a section to motor protection and troubleshooting common faults. It details overload protection mechanisms‚ explaining how to reset tripped breakers and investigate underlying causes like excessive load or voltage issues. The manual guides users through motor winding resistance checks to identify potential short circuits or open windings; It also covers inspecting the motor’s thermal overload relays and ensuring proper ventilation. Understanding the motor’s electrical connections and control circuitry‚ as outlined in the PDF‚ is crucial for accurate diagnosis.

Overload Protection Troubleshooting

The Kaeser compressor PDF manual provides detailed steps for troubleshooting overload protection issues. It emphasizes checking for tripped overload relays‚ often caused by excessive current draw due to a locked rotor or high system pressure. The manual instructs users to verify proper voltage levels and inspect wiring connections for looseness or corrosion. It also details how to reset the overload relay after addressing the root cause. Furthermore‚ the PDF highlights the importance of verifying motor ventilation isn’t obstructed‚ preventing overheating and subsequent trips.

Motor Winding Resistance Checks

The Kaeser compressor PDF manual outlines precise procedures for motor winding resistance checks. It stresses the importance of disconnecting power and utilizing a calibrated ohmmeter for accurate readings. The manual details expected resistance values for each winding‚ allowing for comparison and identification of potential shorts or opens. Significant deviations indicate winding damage‚ requiring motor repair or replacement. It also cautions against performing these checks with the motor energized. Proper documentation of readings‚ as guided by the PDF‚ is crucial for accurate diagnosis.

Control Panel & Display Errors

The Kaeser compressor PDF manual is essential for deciphering control panel and display errors. It provides a comprehensive list of error codes‚ detailing their meaning and potential causes. The manual guides technicians through interpreting these messages‚ offering step-by-step troubleshooting procedures. Reset procedures are clearly outlined‚ specifying the correct sequence to avoid further complications. Understanding the manual’s diagnostic flowcharts is crucial for efficient error resolution. Always refer to the specific model’s PDF‚ as error codes vary; Accurate interpretation minimizes downtime.

Interpreting Error Messages

The Kaeser compressor PDF manual is paramount when interpreting error messages displayed on the control panel. Each code signifies a specific fault‚ ranging from pressure issues to motor problems. The manual details the precise meaning of each code‚ avoiding guesswork. It often categorizes errors by severity‚ indicating immediate action requirements. Cross-referencing the code with the manual’s troubleshooting section is vital. Pay close attention to accompanying symbols or text alongside the code. Accurate interpretation‚ guided by the PDF‚ ensures correct diagnosis;

Control Panel Reset Procedures

The Kaeser compressor PDF manual outlines specific control panel reset procedures‚ crucial after addressing faults. A soft reset‚ often involving a button sequence‚ clears temporary errors without altering settings. A hard reset‚ detailed in the manual‚ restores factory defaults – use cautiously. The manual clarifies when each reset type is appropriate. Incorrect resets can disrupt calibration. Always consult the manual before performing any reset; Document the steps taken for future reference. Following the manual’s guidance prevents unintended consequences and ensures proper system recovery.

Air Filter Maintenance & Issues

The Kaeser compressor PDF manual details essential air filter maintenance schedules and troubleshooting steps. Regular filter replacement‚ frequency specified in the manual‚ prevents compressor damage. Issues like reduced air flow often indicate a clogged filter. The manual explains how to check for excessive pressure drop across the filter. Incorrect filter installation can lead to system inefficiencies. Always use Kaeser-approved filters to maintain warranty compliance. The manual provides diagrams for proper filter placement and sealing. Ignoring filter maintenance impacts air quality and compressor lifespan.

Filter Replacement Frequency

The Kaeser compressor PDF manual precisely outlines filter replacement frequency‚ varying by filter type and operating environment. Typically‚ intake filters require checking monthly and replacement every 6-12 months. Oil separator filters generally need changing annually‚ or after 2000 operating hours. Dusty environments necessitate more frequent inspections and replacements. The manual details specific part numbers for each filter type. Record filter change dates for accurate tracking. Ignoring recommended intervals leads to reduced air quality and compressor inefficiency. Consult the manual for detailed guidance.

Pressure Drop Across the Filter

The Kaeser compressor PDF manual specifies acceptable pressure drop levels across air filters. A significant increase indicates filter clogging‚ restricting airflow and reducing compressor efficiency. Regularly monitor pressure gauges before and after the filter. The manual provides specific pressure drop limits for each filter stage. Exceeding these limits signals an immediate filter replacement is needed. Ignoring excessive pressure drop strains the compressor and increases energy consumption. Document readings for trend analysis. Refer to the manual for detailed troubleshooting steps and diagrams.

Compressor Unloading Problems

The Kaeser compressor PDF manual details the unloading circuit’s operation. Problems often stem from a faulty unloader valve‚ preventing proper pressure regulation during shutdown. Inspect the valve for leaks or sticking. Incorrect pressure switch calibration can also cause issues‚ failing to signal the compressor to unload. The manual provides precise calibration procedures. Check solenoid valves controlling air flow to the unloader. Refer to wiring diagrams within the manual for electrical troubleshooting. Ensure proper air supply to the unloader mechanism.

Unloader Valve Inspection

The Kaeser compressor PDF manual provides detailed diagrams of the unloader valve assembly. Begin by isolating the valve and verifying air supply. Inspect for physical damage‚ corrosion‚ or debris obstructing movement. Disassemble the valve carefully‚ noting the orientation of all components. Check the valve seat for wear or scoring‚ replacing if necessary. The manual specifies torque values for reassembly. Test the valve’s operation using compressed air‚ ensuring it cycles smoothly. A stuck or leaking valve prevents proper compressor unloading.

Pressure Switch Calibration

Refer to the Kaeser compressor PDF manual for precise pressure switch calibration procedures. Incorrect calibration leads to improper compressor operation and potential damage. Use a calibrated pressure gauge to verify the switch’s set points. Adjust the switch according to the manual’s specifications for cut-in and cut-out pressures. Ensure the switch responds accurately to pressure changes. Document the calibration settings for future reference. Regular calibration maintains system efficiency and prevents unnecessary cycling. Always de-energize the compressor before adjusting the switch.

Maintenance Schedule Review

The Kaeser compressor PDF manual details a comprehensive maintenance schedule crucial for longevity. Adhere to recommended service intervals for oil changes‚ filter replacements‚ and separator element changes. A preventative maintenance checklist within the manual outlines daily‚ weekly‚ and monthly tasks. Regular inspections‚ as detailed in the PDF‚ identify potential issues early. Proper maintenance minimizes downtime and maximizes efficiency. Document all maintenance activities for tracking and warranty purposes. Ignoring the schedule can lead to costly repairs and system failures.

Recommended Service Intervals

The Kaeser compressor PDF manual specifies precise service intervals for optimal performance. Oil separation filter elements typically require replacement every 1‚000-2‚000 hours of operation. Air filters should be checked monthly and replaced as needed‚ based on pressure drop. Oil analysis is recommended every 500 hours to monitor lubricant condition. Coolant levels and system integrity should be inspected annually. Valve inspections and overhauls are suggested every 2-3 years. Adhering to these intervals‚ detailed in the PDF‚ prevents costly downtime.

Preventative Maintenance Checklist

Consult the Kaeser compressor PDF manual for a detailed preventative maintenance checklist. Regularly inspect air filters‚ oil levels‚ and coolant conditions. Check for leaks in air lines and connections. Verify proper operation of safety valves and pressure switches. Monitor vibration levels and listen for unusual noises. Clean heat exchangers to maintain efficient cooling. Document all maintenance activities. Following this checklist‚ outlined in the PDF‚ minimizes unexpected failures and extends compressor lifespan. Prioritize safety during all inspections.

Troubleshooting Specific Kaeser Models (e.g.‚ CSD‚ CXC)

Each Kaeser compressor model (CSD‚ CXC‚ etc.) has unique troubleshooting procedures detailed in its specific PDF manual. These manuals outline model-specific error codes‚ component locations‚ and repair instructions. Refer to the correct PDF for your unit to avoid misdiagnosis and potential damage. Pay close attention to diagrams and schematics. Model-specific issues often require specialized tools and knowledge. The PDF provides critical information for effective and safe repairs. Always prioritize the manual’s guidance for optimal results.

Accessing Kaeser Compressor PDF Manuals

Locating the correct Kaeser compressor PDF manual is the first step in effective troubleshooting. Visit the official Kaeser website and navigate to the support or documentation section. Search using your compressor’s serial number or model designation for accurate results. Alternatively‚ authorized Kaeser distributors may provide access to manuals. Ensure the manual corresponds to your specific machine configuration. Downloaded PDFs offer detailed diagrams‚ error code explanations‚ and maintenance schedules. Understanding the manual’s structure is crucial for efficient problem-solving.

Locating the Correct Manual

To pinpoint the precise Kaeser compressor manual‚ begin with the machine’s serial number. This unique identifier ensures compatibility and avoids confusion. The Kaeser website’s support portal is a primary resource‚ offering a searchable database. Input the serial number or model designation for targeted results. If online access proves difficult‚ contact an authorized Kaeser distributor for assistance. Verify the manual’s revision date to confirm it reflects your compressor’s configuration. Incorrect manuals can lead to misdiagnosis and ineffective repairs.

Understanding the Manual’s Structure

Kaeser compressor manuals typically begin with safety precautions and general operating instructions. A dedicated section outlines detailed troubleshooting guides‚ categorized by error codes or symptoms. Pay close attention to exploded diagrams illustrating component locations and assembly. Maintenance schedules‚ lubrication specifications‚ and spare parts lists are crucial for preventative care. The manual often includes technical data‚ such as performance curves and electrical schematics. Familiarize yourself with the index for quick reference to specific topics. Understanding this structure streamlines diagnosis.

Remote Monitoring & Diagnostics

Modern Kaeser compressors often integrate remote monitoring capabilities‚ like the Sigma Air SmartBox; These systems transmit operational data – pressure‚ temperature‚ runtime – for proactive analysis. PDF manuals detail accessing this data and interpreting diagnostic codes remotely; Data logging identifies trends‚ predicting potential failures before they occur. Remote diagnostics minimize downtime by enabling technicians to assess issues without on-site visits. The manual explains network configuration and security protocols for secure data transmission. Utilizing these features enhances troubleshooting efficiency.

Kaeser Sigma Air SmartBox

The Kaeser Sigma Air SmartBox provides real-time compressor performance data‚ accessible via a web interface. PDF manuals detail SmartBox setup‚ including network connectivity and parameter configuration. It monitors key metrics like pressure‚ flow‚ and energy consumption‚ alerting users to anomalies. Troubleshooting guides within the manual explain interpreting SmartBox error messages. Remote access allows technicians to diagnose issues without on-site visits. Data logging features aid in identifying performance trends and potential failures. Secure access protocols are outlined in the documentation.

Data Logging and Analysis

Kaeser compressors‚ particularly when paired with the Sigma Air SmartBox‚ generate extensive operational data logs. PDF manuals detail how to access and interpret this logged information. Analyzing trends in pressure‚ temperature‚ and oil levels can pinpoint developing issues. Historical data assists in identifying recurring problems and evaluating maintenance effectiveness. The manuals explain exporting data for further analysis using specialized software. Proper data analysis can predict potential failures and optimize compressor performance. Troubleshooting guides reference specific data points for diagnostic purposes.

Safety Precautions During Troubleshooting

Before commencing any troubleshooting‚ disconnect the compressor from its power source to prevent electrical hazards. Refer to the Kaeser compressor PDF manual for specific lock-out/tag-out procedures. Compressed air can be dangerous; never direct a stream of air towards personnel. Wear appropriate personal protective equipment (PPE)‚ including safety glasses and gloves. Be mindful of hot surfaces and moving parts. Ensure adequate ventilation when working with oil or solvents. Never attempt repairs beyond your skill level; consult a qualified technician.

Finding Qualified Kaeser Compressor Technicians

Locating a certified Kaeser technician ensures specialized expertise for complex issues. The Kaeser website provides a technician locator tool‚ utilizing your location for nearby service providers. Verify credentials and experience before engaging a technician. Request quotes from multiple technicians‚ detailing the scope of work. A technician familiar with your specific Kaeser model (refer to the PDF manual) is ideal. Confirm warranty implications of third-party repairs. Prioritize technicians offering emergency service options for critical downtime.