instructional writing

What is Instructional Writing?

Instructional writing delivers clear, step-by-step guidance to help someone complete a task – like following a recipe or understanding game rules․

It’s about precise communication, often utilizing imperative verbs, to ensure successful outcomes for the reader, as seen in “How To” guides․

Definition and Purpose

Instructional writing, at its core, is a style of non-fiction text designed to guide an audience through a process․ Its primary purpose is to convey information in a way that enables the reader to successfully replicate a task or understand a set of procedures․

This differs from purely informative writing; it’s action-oriented․ Think of recipes, manuals, or even instructions on how to keep a teacher happy! The goal isn’t just understanding, but doing․

Effective instructional texts empower individuals to achieve a specific outcome, fostering independence and skill development․ They bridge the gap between knowledge and application, making complex tasks accessible through clear, concise direction․

Key Characteristics of Instructional Texts

Instructional texts possess distinct features․ Sequential ordering is paramount – steps must be presented logically, often utilizing numbering or temporal connectors like “first,” “next,” and “finally․”

Clear and concise language is crucial; ambiguity hinders successful completion․ The frequent use of imperative verbs (“mix,” “fold,” “turn”) directly instructs the reader․

Furthermore, these texts often benefit from visual aids, like diagrams, to clarify complex steps․ Analyzing existing texts, such as samosa or paella recipes, reveals these characteristics in practice․ A good instructional text, a WAGOLL, exemplifies these qualities․

Core Elements of Effective Instructions

Effective instructions prioritize clarity, conciseness, and logical sequencing․ Utilizing imperative verbs and precise language ensures readers can easily follow each step to success․

Clear and Concise Language

Clarity is paramount in instructional writing․ Avoid ambiguity and jargon; use straightforward language that your target audience readily understands․ Sentences should be short and direct, focusing on conveying information efficiently․ Eliminate unnecessary words and phrases that could cause confusion․

Conciseness complements clarity․ Get straight to the point, avoiding lengthy explanations or digressions․ Each sentence should serve a specific purpose in guiding the reader through the process․ Think of it as providing only the essential details needed for successful completion․

Remember, the goal is to empower the reader, not overwhelm them with complexity․ Precise wording and a streamlined approach are key to effective instruction․

Use of Imperative Verbs

Imperative verbs are the driving force behind effective instructions․ These action words – like mix, fold, turn, and press – directly tell the reader what to do․ They create a sense of direct address and guide the user through each step of the process․

Using the imperative mood eliminates ambiguity; it’s a clear command, leaving no room for interpretation․ For example, instead of “You should stir the mixture,” write “Stir the mixture․” This directness is crucial for clarity․

Combining imperatives with modal verbs like must or should can add nuance, indicating necessity or recommendation, as seen in examples like “Have to stir carefully․”

Sequential Ordering & Numbering

Clear sequencing is paramount in instructional writing․ Instructions must present steps in the precise order they need to be completed for a successful outcome․ This is best achieved through numbering or using temporal connectors like first, next, then, and finally․

Numbering provides an immediate visual cue, guiding the reader through each stage․ Each step should build logically upon the previous one․ Avoiding jumps or assumptions is vital․

Consider the reader’s perspective; anticipate potential confusion and provide sufficient detail at each stage․ A well-ordered set of instructions minimizes errors and ensures the task is completed correctly․

Types of Instructional Writing

Instructional writing encompasses diverse forms, including recipes, detailed “How To” guides, and precise game rules․ These texts share a common goal: to clearly instruct and guide the reader․

Recipes and Cooking Instructions

Recipes represent a cornerstone of instructional writing, demanding absolute clarity to ensure culinary success․ They meticulously list ingredients and detail preparation steps, often employing precise measurements and temporal connectors like “first,” “next,” and “finally․”

Analyzing recipes, such as those for samosas or paella, provides excellent practice in identifying key instructional elements․ Effective recipes prioritize conciseness, avoiding ambiguity to prevent cooking mishaps․ Before crafting your own, studying existing examples is crucial․

Furthermore, understanding cultural context enhances recipe analysis, offering insights beyond mere technique․ The focus shifts to both textual analysis and appreciating the dish’s origins․

“How To” Guides & Manuals

“How To” guides and manuals exemplify instructional writing’s practical application, offering detailed directions for diverse tasks․ These texts prioritize a sequential ordering of steps, frequently utilizing numbering for enhanced clarity․ They aim to empower readers to independently accomplish a goal, from assembling furniture to operating software․

Like recipes, effective guides employ imperative verbs and concise language, minimizing potential confusion․ KS1 resources often use model texts – WAGOLLs (What A Good One Looks Like) – to demonstrate best practices․

Adapting instructions for varying audiences is key, ensuring accessibility and comprehension for all users․

Game Rules and Instructions

Game rules and instructions represent a crucial form of instructional writing, demanding precision and clarity to ensure fair play and understanding․ These texts meticulously outline objectives, permissible actions, and consequences, often employing sequential ordering and numbering to guide players․

Effective game instructions utilize imperative verbs – “Roll the dice,” “Move your piece” – and avoid ambiguity․ Like “How To” guides, they aim for independent comprehension, allowing players to engage without constant external assistance․

Considering the target audience is vital; rules for children differ from those for experienced gamers․

Planning and Structuring Instructional Texts

Effective planning involves knowing your target audience and meticulously breaking down the process into logical, numbered steps for clarity and ease of following․

Identifying the Target Audience

Understanding who will be using your instructions is paramount․ Are you writing for complete beginners, or individuals with some existing knowledge? This dictates the level of detail and complexity you employ․

For KS1 students, instructions need to be incredibly simple, potentially incorporating WAGOLL (What A Good One Looks Like) examples․ Conversely, instructions for experienced users can be more concise, assuming a base level of understanding․

Consider their age, technical expertise, and cultural background․ Adapting your language and approach ensures accessibility and prevents frustration․ A “How To Keep a Teacher Happy” guide, for example, requires a different tone than instructions for operating a metal detector․

Breaking Down the Process into Steps

Effective instructional writing hinges on dissecting a task into manageable, sequential steps․ Each step should represent a single, achievable action․ Begin with the initial action and progress logically to the final outcome․

Numbering these steps – “First, Next, Then, Finally” – provides clarity and guides the user through the process․ Avoid ambiguity; each instruction must be crystal clear․ Think about a recipe for samosas or paella; each ingredient addition and cooking technique is a distinct step․

Testing your instructions is crucial․ Can someone unfamiliar with the task successfully complete it using only your guidance? Refine and revise until the process is seamless․

Language Features in Instructional Writing

Instructional texts rely on specific language: temporal connectors (“First, Next”), precise adverbs (“Carefully”), and a focus on direct commands to guide the reader effectively․

Temporal Connectors (First, Next, Then, Finally)

Temporal connectors are crucial in instructional writing, acting as signposts that guide the reader through the sequence of steps․ Words like First, Next, Then, and Finally establish a clear chronological order, preventing confusion and ensuring the task is completed correctly․

These connectors aren’t merely stylistic choices; they are fundamental to the text’s functionality; Without them, instructions can become a jumbled list, difficult to follow․ Consider a recipe: “First, preheat the oven․” “Next, combine the ingredients․” “Then, bake for 30 minutes․” “Finally, let cool․”

This structure provides a logical flow, making the process accessible and understandable․ Effective use of these connectors transforms a potentially complex task into a series of manageable steps․

Use of Adverbs to Indicate Precision (Carefully, Gently)

Adverbs play a vital role in instructional writing by adding nuance and precision to the instructions․ Words like Carefully and Gently aren’t simply descriptive; they dictate how an action should be performed, minimizing errors and ensuring desired results․

For example, “Tighten the screw” is adequate, but “Tighten the screw carefully” prevents over-tightening and potential damage․ Similarly, “Mix the ingredients” becomes more effective as “Mix the ingredients gently” when dealing with delicate components․

These adverbs refine the instructions, guiding the user towards a successful outcome․ They demonstrate attention to detail and anticipate potential pitfalls, enhancing the clarity and effectiveness of the instructional text․

Examples and Exercises for Practice

Practice involves analyzing texts like samosa or paella recipes, and crafting instructions for simple tasks – even humorous ones like “Keeping a Teacher Happy”!

Analyzing Existing Instructional Texts (Samosas, Paella)

Examining established recipes, such as those for samosas and paella, provides invaluable insights into effective instructional writing․ Students should dissect these texts, identifying the precise order of steps and the clarity of language used․

Consider how each instruction utilizes imperative verbs and temporal connectors (first, next, then, finally) to guide the cook․ Note the level of detail provided – is anything assumed, or is every action explicitly stated?

Furthermore, analyze how potential challenges or variations are addressed․ Does the recipe offer troubleshooting tips? This analytical approach fosters a deeper understanding of what constitutes strong, user-friendly instructions, preparing students for their own writing endeavors․

Writing Instructions for Simple Tasks (Keeping a Teacher Happy)

Tasking students with writing instructions for a relatable, lighthearted scenario – like “How to Keep a Teacher Happy” – encourages creative application of instructional writing principles․ This exercise allows them to practice using imperative verbs and sequential ordering in a fun, engaging context․

Emphasize the importance of clear, concise language, avoiding ambiguity․ Encourage pupils to consider their target audience (the student body) and tailor their instructions accordingly․

This activity, often utilizing a WAGOLL (What A Good One Looks Like) model, promotes understanding of effective instruction while fostering humor and critical thinking about audience awareness․

Instructional Writing and Text Types (KS1/KS2)

KS1/KS2 instruction focuses on recognizing and utilizing various text types, like instructions, with resources such as writing planners and model texts for effective learning․

Using Model Texts (WAGOLL ─ What A Good One Looks Like)

Model texts, often referred to as WAGOLL (What A Good One Looks Like), are crucial for demonstrating effective instructional writing to students․ These examples showcase the correct structure, language, and formatting expected in instructions․

For instance, a “How To Keep A Teacher Happy” text provides a clear illustration of using imperative verbs and sequential steps․ Analyzing such models helps pupils understand how to present information logically and concisely․

By deconstructing a successful example, students can identify key features like numbered lists, precise language, and the appropriate tone․ This approach fosters confidence and improves their ability to create their own high-quality instructional pieces, adapting the style for different audiences and purposes․

Adapting Instructions for Different Audiences

Effective instructional writing isn’t one-size-fits-all; it requires adaptation based on the intended reader․ Instructions for a child (KS1) will differ significantly from those for an adult or a specialist․

Consider vocabulary – simpler terms are needed for younger audiences․ The level of detail also varies; experts require less explanation․ Visual aids become more important when addressing those with limited literacy or understanding of the topic․

Successfully tailoring instructions demonstrates a strong grasp of communication principles․ It ensures clarity and maximizes the likelihood of the reader successfully completing the task, regardless of their background or expertise․

Advanced Considerations

Advanced instructional writing involves complex scenarios, like guiding someone through a metal detector search, or seamlessly integrating diagrams for clarity and enhanced understanding․

Writing Instructions for Finding Valuable Objects (Metal Detector Scenario)

Crafting instructions for metal detecting requires anticipating user needs and potential challenges․ Begin by outlining safety precautions: always obtain permission, respect private property, and be aware of underground utilities․

Next, detail the metal detector’s operation – power on, ground balance, sensitivity settings․ Explain how to interpret audio signals, differentiating between ferrous and non-ferrous metals․

Crucially, instruct users on proper digging techniques to minimize damage to finds and the environment․ Emphasize careful excavation and recording the find’s location․ Finally, advise on responsible reporting of significant discoveries to local authorities, ensuring preservation of historical artifacts․

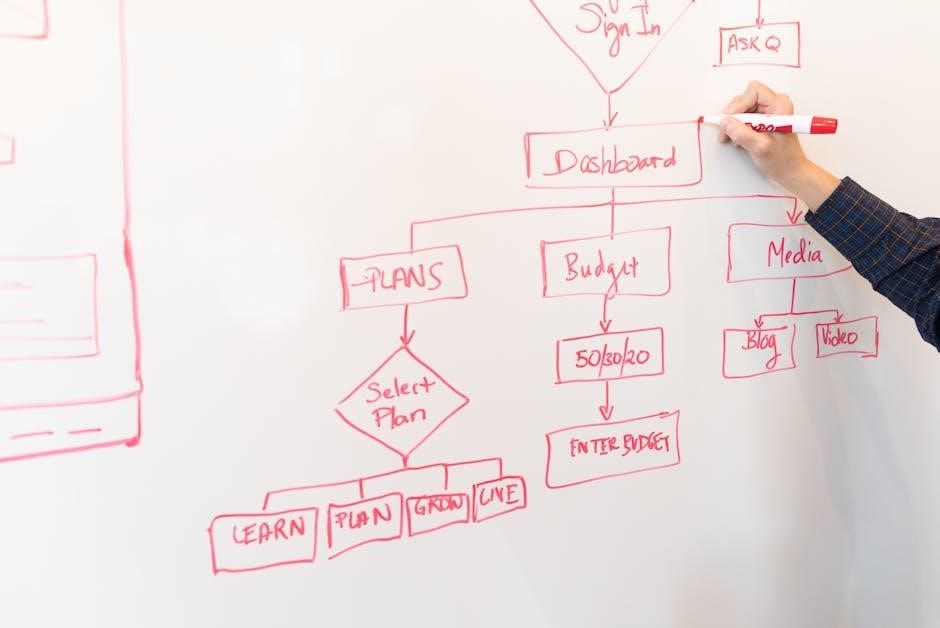

Integrating Visual Aids (Diagrams, Illustrations)

Visual aids dramatically enhance instructional clarity․ Diagrams are invaluable for illustrating complex assemblies or internal mechanisms, simplifying understanding beyond textual descriptions․ Illustrations can demonstrate precise techniques, like the correct angle for a cut or the proper hand position․

Photographs offer realism, showcasing the expected outcome at each step․ Labels and annotations should be concise and directly related to the visual element․

Ensure visuals are high-resolution and logically sequenced alongside the corresponding text․ Effective integration reduces ambiguity and caters to diverse learning styles, boosting comprehension and task success․