grimoire pdf

What is a Grimoire? A Comprehensive Guide to Magical Texts

Grimoires‚ historically‚ are textbooks of magic‚ now often found as PDFs‚ detailing rituals‚ spells‚ and esoteric knowledge.

These digital versions offer accessibility to ancient practices‚

bridging tradition with modern convenience‚ and fostering a renewed interest in magical study.

Online esoteric libraries provide access to digitized grimoires‚

like the Secret Grimoire of Turiel‚ available in PDF format.

The Grimoire Archives offers high-resolution facsimiles and explanations‚

while Open Library catalogs a vast collection of magical texts.

Historical Origins of Grimoires

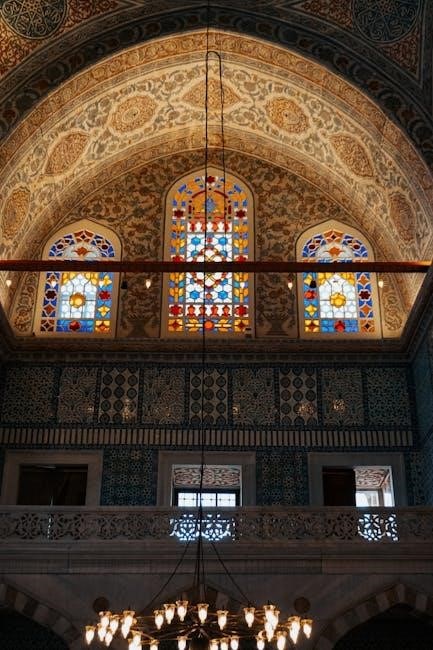

Historically‚ the roots of grimoires trace back to ancient magical traditions‚ evolving through Hellenistic Egypt and the medieval period. Early examples weren’t standardized texts‚ but rather collections of lore‚ recipes‚ and rituals passed down through oral tradition and fragmented manuscripts.

The rise of printing in the 15th and 16th centuries dramatically altered this landscape‚ enabling the wider dissemination of magical knowledge. This era saw the emergence of influential grimoires like the Key of Solomon‚ initially circulated as handwritten manuscripts before becoming widely available in printed PDF-precursor forms.

These early printed grimoires‚ often cloaked in secrecy‚ were frequently associated with Renaissance occultism and the Hermetic tradition. The accessibility afforded by printing‚ and now further enhanced by digital PDF formats‚ fueled the growth of magical communities and the continued evolution of grimoire literature. The digitization of these historical texts allows modern practitioners to study the origins of magical practice.

The Etymology of the Word “Grimoire”

The word “grimoire” itself offers a fascinating glimpse into the history of magical texts. It derives from the Old French word “gramaire‚” meaning grammar. However‚ in medieval times‚ “gramaire” also referred to any book‚ particularly those dealing with Latin grammar – the foundational language of scholarship and‚ importantly‚ magical texts.

Over time‚ the term became specifically associated with books containing occult knowledge‚ likely due to the complex and often obscure language used within them. The association with grammar suggests these books were considered difficult to decipher‚ requiring a specialized “grammar” of magical symbols and rituals.

Today‚ the term retains this aura of mystery and esoteric learning‚ even in the digital realm where grimoires are frequently encountered as PDF documents. The accessibility of these PDFs doesn’t diminish the historical weight of the word‚ but rather extends its reach to a wider audience.

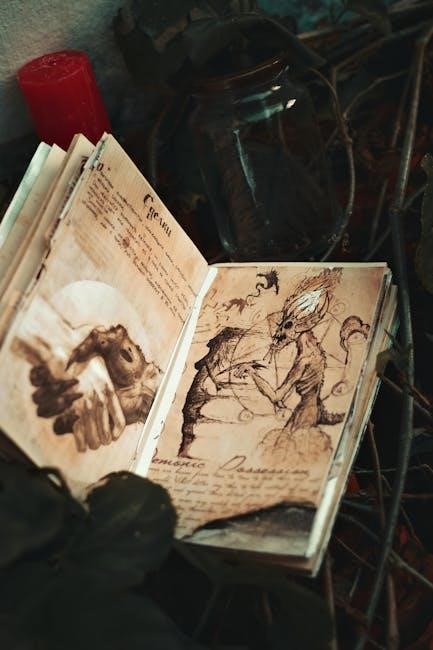

Key Characteristics of Traditional Grimoires

Traditional grimoires‚ even those now available as PDFs‚ share several defining characteristics. They typically contain detailed instructions for invoking spirits‚ creating talismans‚ and performing magical operations. Precise timing – often astrological – is crucial‚ as are specific ritual tools and ingredients.

A common feature is the inclusion of seals or sigils‚ unique symbols representing spirits or forces to be controlled. These are often accompanied by elaborate descriptions of the spirit’s nature and how to safely interact with it. The texts frequently employ coded language and symbolism‚ requiring careful study and interpretation.

Even in PDF format‚ authentic grimoires maintain a sense of antiquity and authority. While digital versions offer convenience‚ they often strive to replicate the original’s layout and imagery‚ preserving the historical context and magical intent.

Popular Grimoires Throughout History

PDF versions of classic texts like The Key of Solomon and Ars Goetia are widely available‚ offering accessible pathways to explore historical magical practices and traditions.

The Key of Solomon

The Key of Solomon‚ a foundational grimoire‚ details ceremonial magic‚ offering instructions for invoking spirits and performing rituals. Numerous PDF copies circulate online‚ allowing modern practitioners to study its complex system of magic. These digital versions often include detailed illustrations and translations‚ enhancing understanding.

Historically‚ the text’s origins are debated‚ with versions appearing across centuries. The grimoire focuses on astrological timing‚ the creation of magical tools‚ and the proper procedures for contacting angelic and demonic entities. Finding a reliable PDF is crucial‚ as variations exist‚ and some may contain inaccuracies or incomplete translations.

Researchers and practitioners alike utilize these PDFs for comparative study‚ analyzing different editions and interpretations. The accessibility of The Key of Solomon in PDF format has significantly contributed to its continued influence within contemporary occultism‚ making its ancient wisdom readily available.

The Lesser Key of Solomon (Ars Goetia)

The Lesser Key of Solomon‚ specifically the Ars Goetia‚ is arguably the most famous section of the larger Key of Solomon. It details the summoning of 72 demons‚ providing descriptions‚ seals‚ and rituals for control. Numerous PDF versions are readily available online‚ making this potent grimoire accessible to a wide audience.

These PDFs often include detailed illustrations of the sigils‚ crucial for successful evocation. However‚ caution is advised; the Ars Goetia is considered advanced magic‚ and improper use can be dangerous. Practitioners should thoroughly research and understand the risks before attempting any of the described rituals.

The proliferation of PDF copies has led to increased study and debate surrounding the text’s authenticity and interpretation. Digital formats allow for easy annotation and cross-referencing‚ aiding in deeper magical exploration. Responsible study and ethical practice are paramount when working with this powerful grimoire in PDF form.

The Heptameron

The Heptameron‚ penned by Pietro d’Abano in the 14th century‚ is a unique grimoire focusing on astrological magic and the invocation of spirits over seven days. Unlike many grimoires centered on demonic evocation‚ The Heptameron emphasizes a more complex system involving planetary hours and specific incantations. Finding a complete‚ reliable PDF version can be challenging due to its relative obscurity.

Available PDFs often present the text in its original Latin‚ requiring translation for most modern practitioners. The grimoire details elaborate rituals designed to gain knowledge and influence through celestial alignment. Digital copies facilitate the study of its intricate tables and correspondences.

Researchers utilize PDF versions for comparative analysis with other grimoires‚ seeking connections and influences. Careful study is crucial‚ as the text’s symbolism is layered and requires a strong foundation in astrology and Kabbalah. Ethical considerations are vital when exploring the magical workings detailed within this ancient PDF.

The Picatrix

The Picatrix‚ also known as the Ghāyat al-Ḥakīm‚ is a highly influential Arabic grimoire of astrological magic‚ translated into Latin in the 13th century. It details the creation of talismans‚ the properties of stones‚ and the invocation of spirits linked to planetary forces. Accessing a complete English PDF translation is a significant boon for modern practitioners‚ as the original texts are complex;

Numerous PDF versions circulate online‚ varying in translation quality and completeness. These digital copies allow for detailed study of the intricate diagrams and tables central to its magical operations. The grimoire’s emphasis on image magic and the creation of astral seals makes it a cornerstone of Renaissance magic.

Researchers utilize PDFs for comparative analysis‚ tracing its influence on later grimoires. Caution is advised when using online PDFs‚ verifying the source and translation accuracy. The Picatrix demands a strong understanding of astrology and a respectful approach to its powerful workings.

Grimoires in the Digital Age: The Rise of Grimoire PDFs

Grimoire PDFs offer unprecedented access to magical texts‚ democratizing esoteric knowledge.

Digital formats preserve rare books and enable easy searching‚ annotation‚ and study for practitioners.

Benefits of Digital Grimoires (PDF Format)

Digital grimoires‚ particularly in PDF format‚ present numerous advantages over traditional‚ physical copies. Accessibility is paramount; rare and historically significant texts‚ once confined to private collections or distant libraries‚ are now readily available online. This democratization of knowledge empowers a wider range of practitioners and researchers.

PDFs facilitate easy searching‚ allowing users to quickly locate specific spells‚ symbols‚ or rituals within a grimoire. Annotation features‚ using PDF software like Rocketbook‚ enable personalized study and the addition of notes‚ interpretations‚ and personal insights directly within the text. Furthermore‚ digital copies eliminate the risk of damage to fragile‚ antique books‚ preserving them for future generations.

Portability is another key benefit; an entire magical library can be stored on a single device‚ accessible anytime‚ anywhere. The ability to easily copy and back up PDF files ensures the safeguarding of valuable magical knowledge. Finally‚ the cost-effectiveness of digital grimoires often makes them a more affordable option than acquiring original or reprinted physical editions.

Where to Find Authentic Grimoire PDFs Online

Locating authentic grimoire PDFs requires careful navigation of the online landscape. Several resources offer digitized versions of historical texts. The Online Esoteric Library provides a collection of PDFs‚ including texts like the Secret Grimoire of Turiel and Libellus Magicus. The Grimoire Archives stands out‚ offering high-resolution facsimiles alongside detailed explanations‚ enhancing understanding.

Open Library serves as a vast‚ editable catalog‚ potentially leading to digitized grimoires. However‚ verifying authenticity is crucial. Internet Archive often hosts scanned copies of older books‚ including magical texts‚ but copyright status should be checked. Spaces‚ accessible via the Spaces app and Sara Jane Art Magic‚ provides course tutorials and community access‚ potentially linking to resources.

Be cautious of websites offering “free” grimoires‚ as these may contain misinformation or be of questionable legality. Prioritize established archives and libraries‚ and always cross-reference information to ensure accuracy and avoid fraudulent materials.

Legality and Copyright Considerations

When accessing grimoire PDFs online‚ understanding legality and copyright is paramount. Many historical grimoires are now in the public domain‚ allowing for free distribution of digitized versions. However‚ newer translations or editions may still be protected by copyright‚ restricting unauthorized reproduction or sharing.

Websites offering PDFs should ideally indicate the copyright status of the material. Downloading copyrighted material without permission constitutes infringement. Be wary of sites offering seemingly “free” copies of recently published works‚ as these are likely illegal.

Resources like Internet Archive often specify copyright information. Always respect intellectual property rights and consider purchasing legitimate copies to support authors and publishers. Utilizing public domain texts responsibly ensures ethical access to this rich magical heritage‚ avoiding potential legal repercussions.

Understanding the Content of Grimoire PDFs

Grimoire PDFs contain diverse magical content – rituals‚ spells‚ and symbolic systems. Deciphering symbols‚ sigils‚ and understanding their interpretations unlocks the texts’ deeper meanings and practical applications.

Types of Magical Content Found in Grimoires

Grimoire PDFs showcase a remarkable breadth of magical practices. Commonly‚ you’ll encounter detailed instructions for evocation – summoning spirits‚ often categorized as outlined in texts like the Ars Goetia‚ a section of the Lesser Key of Solomon. These PDFs frequently include specific rituals for contacting these entities‚ alongside descriptions of their attributes and seals.

Beyond evocation‚ grimoires delve into ceremonial magic‚ encompassing elaborate rites for achieving specific goals‚ such as gaining knowledge‚ attracting love‚ or influencing events. Herbalism and alchemy also feature prominently‚ detailing the properties of plants and substances used in spellwork. Many Grimoire PDFs contain extensive sections on talismanic magic‚ explaining how to create and consecrate objects imbued with magical power.

Furthermore‚ you’ll find astrological correspondences‚ linking planetary energies to magical operations‚ and instructions for creating sigils – symbolic representations of intent. The content within these digital texts aims to provide a comprehensive system for interacting with the unseen forces believed to govern the universe.

Symbols‚ Sigils‚ and Their Interpretation

Grimoire PDFs are replete with intricate symbols and sigils‚ acting as keys to unlocking magical energies. Sigils‚ unique symbolic representations of desired outcomes‚ are a core component‚ often created through specific methods detailed within the texts. Their interpretation isn’t arbitrary; grimoires provide guidelines for their construction and activation‚ linking them to planetary forces or spirit names.

Beyond sigils‚ you’ll find a wealth of other symbols – astrological glyphs‚ alchemical emblems‚ and Kabbalistic diagrams – each carrying layers of meaning. Understanding these symbols requires dedicated study‚ as PDF versions often lack the contextual explanations found in traditional teachings.

Many grimoires emphasize the importance of correct rendering and visualization of these symbols‚ believing their power lies in precise execution. The PDF format allows for close examination‚ but careful cross-referencing with scholarly resources is crucial for accurate interpretation and effective magical practice.

Rituals and Spellwork Explained

Grimoire PDFs meticulously outline rituals and spellwork‚ often detailing precise timings‚ required materials‚ and incantations. These instructions aren’t merely suggestions; they’re presented as essential components for successful operation. The digital format allows for easy searching and referencing of complex procedures‚ a significant advantage over older manuscripts;

However‚ simply copying instructions from a PDF isn’t enough. Grimoires often assume a foundational understanding of magical principles and correspondences. Successful spellwork requires careful preparation‚ focused intention‚ and a deep respect for the energies being invoked.

Many rituals involve elaborate ceremonies‚ demanding specific tools and atmospheric conditions. Rocketbook‚ for example‚ can aid in documenting these practices. While PDFs provide the framework‚ the practitioner’s skill and dedication are paramount to achieving desired results.

Tools for Working with Grimoire PDFs

Grimoire PDFs benefit from digital annotation software‚ like those used with Rocketbook‚ for note-taking. Digital notebooks and online esoteric libraries‚ such as Open Library‚

enhance study.

PDF Annotation Software for Magical Study

Grimoire PDFs truly come alive with the right annotation tools‚ transforming static texts into dynamic workspaces for magical practitioners. Software allows direct markup of spells‚ rituals‚ and symbolic interpretations within the PDF itself‚ fostering deeper engagement and personalized understanding.

Consider Rocketbook as a prime example; its combination of physical notebook and digital transfer offers a unique workflow. Write rituals traditionally‚ then digitize for organization and backup. Other PDF editors enable highlighting key passages‚ adding notes on correspondences‚ and even drawing sigils directly onto the pages.

These digital layers become invaluable for tracking progress‚ identifying patterns‚ and building a customized magical lexicon. The ability to search within PDFs is also crucial‚ quickly locating specific spells or symbols. Ultimately‚ annotation software empowers a more interactive and insightful study of grimoire content.

Digital Notebooks and Grimoire Organization

Managing a collection of Grimoire PDFs requires robust organization‚ and digital notebooks offer a compelling solution. Beyond simply storing files‚ these platforms allow for categorization‚ tagging‚ and cross-referencing of magical content. Think of them as a personalized‚ searchable library tailored to your practice.

Rocketbook‚ with its blend of physical writing and digital archiving‚ presents a hybrid approach. Rituals are first recorded by hand‚ then seamlessly transferred to a digital format for organization. Alternatively‚ dedicated note-taking apps can house PDF annotations‚ research notes‚ and personal insights‚ all linked to specific grimoires.

Effective organization involves creating a logical system – by magical tradition‚ elemental association‚ or spell type‚ for example. This ensures quick retrieval of information when needed‚ fostering a more fluid and productive magical workflow. A well-structured digital grimoire is a powerful asset.

Online Esoteric Libraries and Resources

The internet provides unprecedented access to a wealth of Grimoire PDFs and related esoteric resources. Open Library stands out as a vast‚ editable catalog aiming to document every published book‚ including many magical texts. This allows for discovery and borrowing of digitized grimoires.

The Grimoire Archives is a dedicated collection of significant magical textbooks‚ offering high-resolution facsimiles alongside detailed explanations. This resource is invaluable for serious students seeking to understand the historical context and intricacies of these texts.

Furthermore‚ numerous websites host individual PDF copies of classic grimoires‚ such as the Secret Grimoire of Turiel and Libellus Magicus. Careful vetting is crucial‚ ensuring authenticity and avoiding misinformation. Exploring these digital libraries unlocks a treasure trove of magical knowledge.

Cautions and Ethical Considerations

Grimoire PDFs demand responsible practice; avoid misinformation and fraudulent texts. Respect traditions‚ origins‚ and practice ethically‚ understanding the power within these ancient magical documents.

The Importance of Responsible Magical Practice

Grimoire PDFs‚ while offering incredible access to magical knowledge‚ necessitate a strong foundation of responsible practice. Approaching these texts without proper understanding or respect can lead to unintended consequences‚ both for the practitioner and those around them. It’s crucial to remember that the rituals and spells contained within are not simply games or experiments.

Before attempting any work detailed in a grimoire PDF‚ thorough research and self-reflection are paramount. Consider the ethical implications of your actions and the potential impact on others. A mindful approach‚ coupled with a commitment to personal growth‚ is essential. Avoid impulsive spellcasting or blindly following instructions without comprehending the underlying principles.

Furthermore‚ remember that magical practice is a journey of self-discovery‚ not a quick fix for life’s problems. Treat these ancient texts with reverence and acknowledge the lineage of knowledge they represent. Responsible practice ensures safety‚ efficacy‚ and a deeper connection to the magical arts.

Avoiding Misinformation and Fraudulent Grimoires

The proliferation of Grimoire PDFs online presents a significant risk of encountering misinformation and outright fraudulent texts. Not all sources are created equal‚ and discerning authentic material from fabricated content is crucial for any serious practitioner. Beware of texts promising instant power or overly simplistic solutions – genuine grimoires often require dedicated study and practice.

Cross-reference information found in one PDF with multiple sources‚ consulting established esoteric libraries and scholarly works. Look for texts with clear historical provenance and avoid those lacking attribution or appearing suspiciously modern in language. Be wary of sellers offering “rare” or “lost” grimoires at exorbitant prices; these are often scams.

Prioritize resources from reputable online archives and communities. Remember‚ critical thinking and skepticism are your best defenses against misleading information within the digital realm of grimoires.

Respecting the Traditions and Origins of Grimoires

When engaging with Grimoire PDFs‚ it’s paramount to approach these texts with respect for their historical and cultural origins. These aren’t simply collections of spells; they represent centuries of esoteric tradition‚ often rooted in specific religious or philosophical frameworks. Understanding this context is vital for responsible practice.

Avoid treating grimoires as mere tools for personal gain‚ disregarding the ethical considerations embedded within their teachings. Many traditions emphasize the importance of lineage and initiation; attempting practices without proper grounding can be disrespectful and potentially harmful.

Recognize that the digitization of these texts‚ while increasing accessibility‚ also carries a responsibility to preserve their integrity. Acknowledge the authors and traditions from which they stem‚ and approach their contents with humility and reverence.