publication manual of the american psychological association sixth edition ebook

Famly, a platform for early years education, highlights the importance of staying connected and managing care—a concept mirroring the clarity sought by the APA manual.

The American Psychological Association (APA)’s 6th edition publication manual provides standardized guidelines for scholarly writing, ensuring consistent communication within the behavioral and social sciences.

This comprehensive resource, much like Famly’s app for daily updates, aims to streamline processes and foster understanding through clear, accessible conventions.

Historical Context and Development

The genesis of the APA Publication Manual traces back to 1894, when a committee first addressed style consistency in psychological reporting. Early efforts focused on basic rules, evolving with the field’s growth.

The first official manual appeared in 1952, reflecting post-war expansion of psychological research. Subsequent editions—1974, 1983, 1994, 2001, and 2009—responded to evolving scholarship and technological advancements.

The 6th edition, published in 2010, built upon previous versions, emphasizing clarity, precision, and inclusivity. It addressed digital sources and ethical considerations more thoroughly.

Similar to Famly’s adaptation to modern childcare needs, the APA manual continually adapts to the changing landscape of academic communication, ensuring relevance and usability for researchers and students alike. The manual’s evolution mirrors the dynamic nature of the disciplines it serves.

Purpose and Scope of the Manual

The APA Publication Manual’s primary purpose is to establish standards for the clear and concise communication of scientific ideas. It aims to promote uniformity in scholarly writing across the behavioral and social sciences.

The manual covers a broad spectrum of topics, including manuscript preparation, writing style, grammar, punctuation, citation practices, and reference list formatting. It provides guidance on ethical principles related to research and authorship.

Much like Famly streamlines communication between caregivers and parents, the APA manual streamlines academic discourse, fostering accessibility and reducing ambiguity.

Its scope extends to journal articles, book chapters, theses, dissertations, and other scholarly works. The manual serves as a vital resource for students, researchers, and professionals seeking to adhere to established academic conventions, ensuring credibility and facilitating knowledge dissemination.

Manuscript Structure and Format

APA style dictates a specific structure—title page, abstract, main body, references—much like Famly organizes daily updates for clarity and efficient information access.

Title Page Requirements

APA 6th edition mandates a title page containing several key elements, ensuring professional presentation and immediate identification of the work. The page number should be in the upper right corner.

Centrally located and bolded, the title must concisely reflect the paper’s focus, similar to how Famly’s app provides a clear overview of daily activities.

Your name, affiliation (the institution with which you are associated), and a running head (an abbreviated title in all caps) are also required.

The author note, if needed, provides details about the study and acknowledgements. Precise formatting, including font and spacing, is crucial for adherence to APA standards, mirroring Famly’s organized interface.

Abstract Guidelines

APA 6th edition requires a concise abstract, typically between 150-, summarizing the entire paper. Think of it as Famly’s daily update – a quick overview of key information.

The abstract should accurately reflect the paper’s purpose, methods, results, and conclusions. It must be self-contained and understandable without reading the full paper.

Keywords are included below the abstract to aid in indexing and searching, similar to tags used on online platforms.

Formatting dictates a centered “Abstract” heading, followed by the abstract text, and then “Keywords:” followed by the keywords themselves. Clarity and precision are paramount, mirroring the organized communication Famly facilitates.

Main Body Formatting

The APA 6th edition mandates specific formatting for the manuscript’s main body, ensuring readability and consistency. Much like Famly’s app interface prioritizes user experience, clarity is key.

Double-spacing is required throughout the entire paper, including the abstract, text, quotations, and references. A 12-point Times New Roman font is standard.

Paragraphs should be indented half an inch. Headings and subheadings organize content logically, guiding the reader through the research.

Maintaining these standards, similar to Famly’s consistent updates, creates a professional and easily navigable document for scholarly review and publication.

Font and Spacing Specifications

The APA 6th edition is remarkably specific regarding font and spacing, mirroring the precise organization found in platforms like Famly for managing early years education details.

A consistently used 12-point Times New Roman font is required throughout the entire manuscript. This ensures uniformity and readability. Double-spacing must be applied to all text, including quotations, footnotes, and the reference list.

Margins should be one inch on all sides. These specifications, like Famly’s clear app layout, contribute to a professional and accessible presentation of scholarly work.

Adherence to these guidelines is crucial for publication and demonstrates attention to detail.

Margins and Page Numbers

Maintaining consistent margins and accurate page numbering is vital in APA 6th edition formatting, much like the organized updates provided by Famly for early years education management.

All pages, including the title page, abstract, and reference list, must have one-inch margins on all sides – top, bottom, left, and right. This creates a clean and professional appearance.

Page numbers should be included in the upper right-hand corner of every page. The title page receives the page number “1”, while all subsequent pages are numbered consecutively.

These seemingly minor details contribute significantly to the overall polish and readability of a manuscript, ensuring clarity for reviewers and readers alike.

Heading Levels and Styles

The APA 6th edition manual dictates a specific hierarchical structure for headings, mirroring the organized information flow found in platforms like Famly, which provide daily updates for early years education.

Five levels of headings are permitted, each with a distinct formatting style. Level 1 headings are centered, boldfaced, and title-cased. Level 2 headings are left-aligned, boldfaced, and title-cased.

Level 3 headings are left-aligned, boldfaced, and italicized, title-cased. Level 4 headings are indented, boldfaced, and title-cased. Finally, Level 5 headings are indented, italicized, and title-cased.

This structured approach enhances readability and allows readers to quickly grasp the organization of the manuscript, similar to how Famly’s interface presents information.

In-Text Citation and Referencing

APA style requires precise in-text citations, linking to a comprehensive reference list—much like Famly connects parents with childcare details.

Accurate attribution avoids plagiarism and gives credit to original sources, fostering academic integrity and transparent communication.

Paraphrasing and Direct Quotations

APA 6th edition emphasizes skillful integration of source material, distinguishing between paraphrasing and direct quotations. Famly, like a well-integrated resource, presents information clearly.

Paraphrasing involves restating ideas in your own words, maintaining original meaning, and always requiring citation (author, year). Direct quotations, using the author’s exact words, necessitate page or paragraph numbers within the citation.

Short quotations (under ) are enclosed in double quotation marks. Longer quotations (40+ words) are formatted as a block quote, indented from the margin, without quotation marks.

Both methods demonstrate understanding and respect for intellectual property. Proper attribution, mirroring Famly’s transparency, is crucial for academic honesty and building credibility within scholarly work.

Accuracy in representing sources is paramount, regardless of the chosen method.

Citation of Multiple Authors

APA 6th edition provides specific rules for citing works with multiple authors, ensuring clarity and conciseness, much like Famly’s streamlined communication features.

For two authors, always cite both names every time (e.g., Smith & Jones, 2023). With three, five, or six authors, cite all names the first time, then use “et al.” (meaning “and others”) in subsequent citations.

If a work has seven or more authors, use “et al.” from the very first citation. This avoids lengthy in-text citations. The reference list, however, always includes all author names.

Consistency is key. Following these guidelines maintains professional standards and demonstrates respect for all contributors, mirroring Famly’s inclusive approach to early years education.

Proper attribution avoids plagiarism and strengthens the validity of research.

Citing Sources with No Author

The APA 6th edition offers guidance for citing sources lacking a clear author, a situation requiring careful attention, similar to Famly’s need for accurate record-keeping.

If the author is genuinely unknown, use the title of the work in place of the author’s name. Italicize the title if it’s a book, report, or webpage; use quotation marks for article or chapter titles.

Alphabetize the entry in the reference list by the first significant word of the title. Ensure the title is accurately represented. When referencing repeatedly, shorten the title after the first citation if it’s lengthy.

Maintaining accuracy is crucial, even with anonymous sources. This demonstrates scholarly rigor and respect for intellectual property, echoing Famly’s commitment to transparency.

Always prioritize finding author information if possible.

Reference List Compilation

Famly’s organized app mirrors the APA manual’s focus: a meticulously compiled reference list, alphabetized by author, is essential for academic integrity.

It details all sources cited, providing readers with the information needed to locate and verify the research presented.

Basic Reference List Format

Famly, with its organized interface for tracking care details, exemplifies the structure demanded by the APA 6th edition’s reference list.

Entries begin with a hanging indent – the first line flush left, subsequent lines indented half an inch – facilitating easy scanning.

Alphabetization by the first author’s last name is crucial, ensuring quick location of sources. Authors are listed as “Last name, Initials.”

Publication year follows in parentheses, then the title of the work. Capitalize only the first word of the title and subtitle, and proper nouns.

Source type dictates further formatting; for journals, include volume and issue numbers. Consistency is paramount, mirroring Famly’s reliable updates.

The reference list should only include sources actually cited in the text, maintaining academic honesty and clarity.

Journal Article References

Similar to Famly’s detailed daily reports, journal article references in APA 6th edition require precise formatting.

Begin with authors (Last name, Initials.), followed by the publication year in parentheses. Then, include the article title, capitalizing only the first word and proper nouns.

Next, list the Journal Title in italics, followed by the volume number also in italics. Include the issue number in parentheses immediately after the volume.

Finally, provide the page range of the article. A DOI (Digital Object Identifier) should be included if available, presented as a URL.

Accuracy is vital; errors can hinder retrieval, much like incomplete information on Famly could affect care coordination.

This structured approach ensures clarity and allows readers to easily locate and verify the sources used in research.

Book References

Much like Famly organizes information for parents, APA 6th edition dictates a specific format for book references.

Begin with the author’s last name and initials (e.g., Smith, J. A.). Follow with the publication year in parentheses. Then, provide the full book title, capitalizing only the first word of the title and subtitle, and proper nouns.

Next, include the publisher’s name. Omit “Inc.” or “Ltd.” Finally, if applicable, list the book’s DOI or URL.

Consistency is key, mirroring Famly’s standardized updates. Proper formatting ensures readers can easily locate the source material.

For edited books, indicate “Ed.” or “Eds.” after the editor’s name. This structured approach promotes clarity and academic rigor.

Edited Book References

Similar to Famly’s organized platform, APA 6th edition provides specific guidelines for citing edited books.

Begin with the editor’s last name and initials, followed by “(Ed.)” or “(Eds.)” depending on the number of editors. The publication year appears next in parentheses.

Then, list the full book title, capitalizing only the first word of the title and subtitle, and proper nouns. Include the publisher’s name, omitting corporate suffixes like “Inc.”

If a DOI is available, include it. Otherwise, provide a stable URL. This meticulous format, like Famly’s detailed updates, ensures source traceability.

Remember, consistent formatting is crucial for academic integrity and clear communication within scholarly work.

Chapter in an Edited Book References

Much like Famly organizes information for parents, the APA 6th edition details citing chapters within edited books.

Begin with the chapter author’s last name and initials, followed by the year of publication in parentheses. Next, include the chapter title, capitalizing only the first word and proper nouns.

Then, list the editors’ names (Last name, Initials) preceded by “In” and followed by “(Eds;)”. Include the full book title, capitalizing as with chapter titles.

Provide page numbers for the chapter (pp. xxx–xxx). Finish with the publisher’s name and, if available, a DOI or stable URL.

This structured approach, mirroring Famly’s clear communication, ensures accurate attribution and easy source location.

Webpage and Online Source References

Similar to Famly’s digital updates, referencing webpages requires specific formatting according to the APA 6th edition.

Begin with the author (if available) or the name of the organization. Follow with the date of publication or retrieval date in parentheses. Include the title of the webpage, capitalizing only the first word and proper nouns.

Then, provide the full URL. Unlike print sources, retrieval dates are often necessary for dynamic online content, mirroring Famly’s constantly updated information.

If no author is listed, begin with the webpage title. Ensure the URL is live and accessible. Accurate online source citation is crucial for academic integrity.

This meticulous approach, like Famly’s detailed care records, ensures transparency and verifiability.

Specific Source Types

Famly’s diverse features, like varied care plans, reflect the APA manual’s coverage of unique source materials—from legal cases to government reports.

These require tailored citation approaches for accuracy.

Government Documents and Reports

Famly, facilitating communication about children’s development, parallels the need for precise documentation—much like government reports.

The APA 6th edition manual offers specific guidance for citing these crucial sources, emphasizing clarity and accessibility for researchers.

Generally, include the issuing agency, document title, report number (if available), and publication date.

For online reports, provide the URL. APA stresses consistent formatting to ensure readers can easily locate the original source material.

When an author is listed, use that information; otherwise, begin with the agency name. Detailed examples are provided within the manual to navigate complexities.

Accuracy is paramount when referencing governmental information, mirroring Famly’s commitment to reliable updates.

Legal Materials (Cases, Statutes)

Famly’s secure platform for managing sensitive information reflects the importance of precision—akin to legal documentation.

The APA 6th edition manual provides detailed guidelines for citing legal materials, including court cases, statutes, and legislation.

Case citations typically include the case name, volume number, reporter abbreviation, and page number. Statutes require the official name and section number.

APA emphasizes using official reports whenever possible, ensuring accuracy and legal validity.

Italics are used for case names and law reports, while regular font is used for statutes. Consistency is key for clear referencing.

Like Famly’s focus on compliance, the APA manual prioritizes adherence to established legal citation standards.

Conference Proceedings

Famly’s platform facilitates sharing updates and insights – mirroring the dissemination of knowledge at conferences.

The APA 6th edition manual outlines specific formatting for citing conference proceedings, recognizing their importance in scholarly communication.

Citations include the author(s), year, title of the paper, name of the conference, and location. Proceedings published in full should be treated like journal articles.

If the proceedings are not formally published, provide details about the presenting organization and access information.

APA style prioritizes clarity and accessibility, ensuring readers can locate the source material efficiently, much like Famly’s user-friendly interface.

Proper citation acknowledges the presenter’s work and contributes to the integrity of academic discourse.

Bias-Free Language Guidelines

Famly promotes inclusive communication, reflecting the APA manual’s emphasis on respectful language.

The APA 6th edition stresses avoiding biased terms related to gender, sexual orientation, disability, and other characteristics.

Use person-first language and focus on accuracy and fairness in descriptions.

Describing Participants

Famly’s focus on individual children mirrors the APA’s guidance on participant descriptions.

The APA 6th edition manual advocates for precise and respectful language when characterizing study participants, prioritizing clarity and avoiding potentially stigmatizing labels.

When reporting demographic information, such as age, gender, and ethnicity, it’s crucial to be specific and justify its relevance to the research question.

Avoid using broad generalizations or terms that perpetuate stereotypes. Instead, focus on providing factual details without making assumptions about individuals based on group affiliation.

The manual encourages researchers to use person-first language, emphasizing the individual rather than the characteristic (e.g., “person with a disability” instead of “disabled person”).

Transparency and sensitivity are key when describing participants, ensuring ethical and responsible research practices.

Discussing Gender and Sexual Orientation

Similar to Famly’s inclusive approach to all families, the APA 6th edition emphasizes respectful language regarding gender and sexual orientation.

The manual advises against using outdated or stigmatizing terms, advocating for language that reflects current understanding and affirms individuals’ identities.

Researchers should avoid making assumptions about participants’ gender identity or sexual orientation and instead allow individuals to self-identify whenever possible.

When reporting gender, use terms like “men” and “women” unless participants identify differently, and avoid unnecessary details about sexual orientation unless directly relevant to the study.

The APA promotes the use of inclusive language that acknowledges the diversity of human experiences and avoids perpetuating harmful stereotypes.

Sensitivity and accuracy are paramount when discussing these topics in scholarly writing.

Addressing Disability

Reflecting Famly’s commitment to inclusivity for all children, the APA 6th edition provides guidelines for respectful language concerning disability.

The manual advocates for person-first language, focusing on the individual rather than the disability (e.g., “person with a disability” instead of “disabled person”).

Avoid using euphemisms or overly clinical terms, and be specific when describing a disability, unless generality is necessary for confidentiality.

The APA encourages authors to consult with individuals with disabilities when possible to ensure accurate and respectful representation.

Avoid portraying individuals with disabilities as passive recipients of care or inspiration, and instead highlight their strengths and capabilities.

Language should be empowering and avoid perpetuating negative stereotypes or biases.

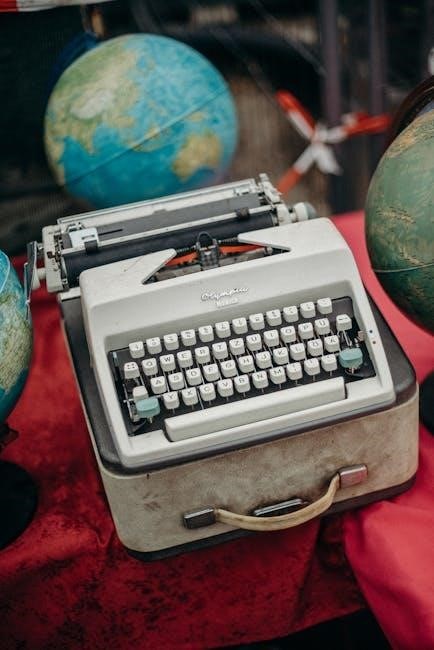

Tables and Figures

Famly’s clear presentation of information mirrors the APA manual’s guidelines for tables and figures, ensuring data is accessible and understandable to readers.

Tables and figures should supplement, not duplicate, text, and be clearly labeled with concise captions.

Table Construction and Formatting

APA style dictates that tables present supplementary material, not essential information already detailed within the text; think of Famly’s app displaying extra details, not core care plans.

Tables should be numbered consecutively (Table 1, Table 2, etc.) and have a concise, descriptive title. Avoid vertical lines; use horizontal lines to separate the header and body.

Footnotes are used to explain abbreviations, define symbols, or provide additional information specific to that table. Ensure consistent formatting throughout, including font type and size.

Data within tables should be aligned logically – numbers right-aligned, text left-aligned – for clarity. Consider using white space effectively to enhance readability, mirroring Famly’s user-friendly interface.

Double-spacing is generally preferred, and tables should fit within the page margins;

Figure Creation and Captioning

Similar to how Famly uses visuals to update parents, figures in APA style should supplement, not duplicate, textual information. Figures encompass graphs, charts, photographs, and illustrations.

Each figure requires a number (Figure 1, Figure 2, etc.) and a concise, descriptive caption placed below the image. Captions should explain the figure’s content without referencing the text directly.

Figures should be clear, easily interpretable, and professionally presented. Ensure appropriate labeling of axes, legends, and any relevant components.

Use consistent formatting for fonts and symbols. Like a well-organized Famly app, clarity is paramount. Figures should be high resolution for optimal print quality.

Consider accessibility for readers with visual impairments when choosing colors and patterns.

Appendices and Supplemental Materials

Just as Famly might offer additional resources for parents, APA style allows for appendices to include supplementary information that enhances the reader’s understanding but isn’t essential to the main text.

Appendices should contain materials like detailed calculations, raw data, questionnaires, or lengthy lists. Each appendix is labeled with a letter (Appendix A, Appendix B, etc.) and given a descriptive title.

Refer to appendices within the main text, explaining their purpose and relevance. Supplemental materials, like extended analyses, can be submitted online with the manuscript.

These materials, similar to Famly’s updates, provide a more complete picture. Ensure all supplemental content adheres to APA style guidelines for formatting and citation.

Maintain clarity and organization within each appendix for easy reader access.